Imikhiqizo

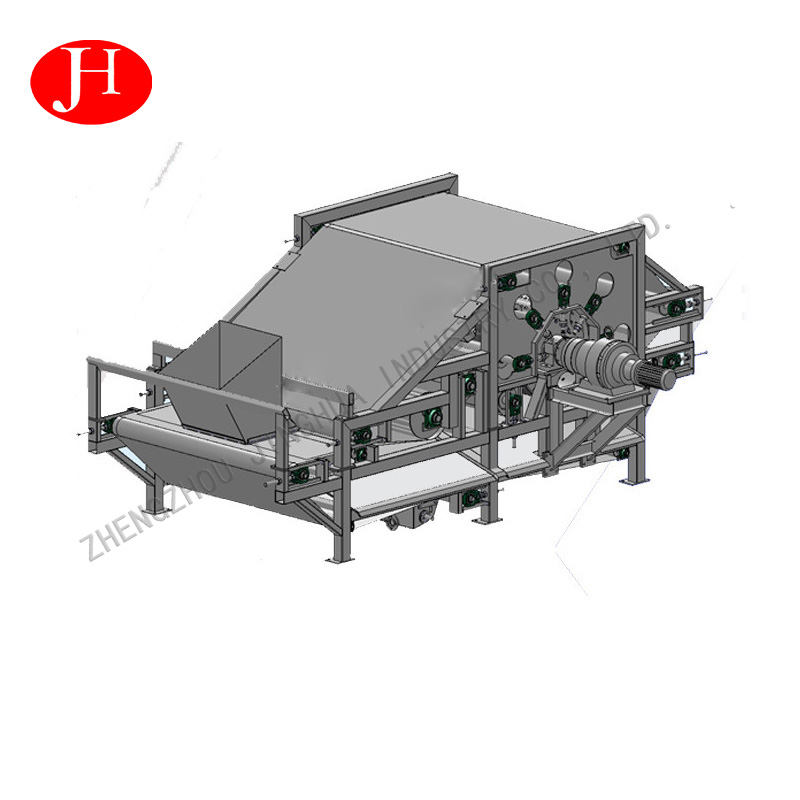

I-Fiber Dehydrator yokucubungula isitashi

Imingcele yezobuchwepheshe eyinhloko

| Imodeli | Amandla (Kw) | Ububanzi bebhande lokuhlunga (mm) | Isivinini sebhande lokuhlunga (m/s) | Amandla (Ngaphambi kokuphelelwa amanzi)(kg/h) | Ubukhulu (mm) |

| I-DZT150 | 3.3 | 1500 | 0-0.13 | ≥5000 | 4900x2800x2110 |

| I-DZT180 | 3.3 | 1800 | 0-0.13 | ≥7000 | 5550x3200x2110 |

| I-DZT220 | 3.7 | 2200 | 0-0.13 | ≥9000 | 5570x3650x2150 |

| I-DZT280 | 5.2 | 2800 | 0-0.13 | ≥10000 | 5520x3050x2150 |

Izici

- 1Umkhiqizo uthuthukiswa ngokuzimela yinkampani, ngemizamo yocwaningo lwesayensi ye-Henan University of Technology.

- 2Isiphakeli esimise okwe-Wedge singaqinisekisa izinto ezisatshalaliswa ngokulinganayo kubhande lokuhlunga elinogqinsi olulungisekayo.

- 3Isistimu yokugoqa ephelelwe amanzi emzimbeni yenza ishubhu engenamthungo futhi isongwe ngenjoloba ekwazi ukumelana nokugqokwa kwekhwalithi ephezulu, Ithembekile ngempilo ende yesevisi.

Bonisa Imininingwane

I-hopper yensalela yamazambane ibekwe isicaba ebhandeni lesihlungi elingezansi ngesigaba sokuphakela esimise okwe wedge.

Khona-ke izinsalela zamazambane zingena endaweni yokucindezela neyokukhipha amanzi emzimbeni. Insalela yamazambane isatshalaliswa ngokulinganayo phakathi kwamabhande amabili okuhlunga futhi ingena endaweni ye-wedge futhi iqala ukuminyanisa futhi ikhiphe amanzi. Ngemva kwalokho, izinsalela zamazambane zibanjwe amabhande amabili okuhlunga, akhuphuka futhi awe izikhathi eziningana. Izikhundla zezingqimba zangaphakathi nangaphandle zamabhande amabili okuhlunga ku-roller zishintsha njalo, ukuze ungqimba lwezinsalela zamazambane luhlale lugudlukile futhi lugunda, futhi inani elikhulu lamanzi likhishwa ngaphansi kwamandla okucindezela kwebhande lokuhlunga. Khona-ke insalela yamazambane ingena endaweni yokucindezela nokukhipha amanzi. Ngaphansi kwesenzo sama-roller amaningana acindezelayo engxenyeni engenhla ye-roller yokushayela, i-dislocation shear kanye ne-extrusion ikhiqizwa ngokuqhubekayo.ngesikhathi senqubo yokucindezela, ama-dregs amazambane asuswa kalula ebhande lokuhlunga.

Izinsalela zamazambane zithunyelwa kudivayisi yokukhuhla ngokusebenzisa i-roller ehlehlayo, futhi ngemva kokuchithwa yi-scraping device, ingena esigabeni esilandelayo.

Ububanzi Besicelo

Ubhatata isitashi, isitashi se-tapioca, isitashi samazambane, isitashi sikakolweni, isitashi sombila, isitashi sephizi, njll. (ukumiswa kwesitashi) amabhizinisi okukhiqiza isitashi.